ALUCOBOND® A2

ALUCOBOND® A2 is our non-combustible aluminium composite panel used in architecture that fulfills the respective standards worldwide. Thanks to its mineral-filled core, ALUCOBOND® A2 meets the strict requirements of the fire regulations and enhances the possibilities for the concept and design of buildings. ALUCOBOND® A2, just like all the products of the ALUCOBOND® family, allows simple processing, is impact-resistant, break-proof and weatherproof and, above all, non-combustible.

- Description

PRODUCT PROPERTIES

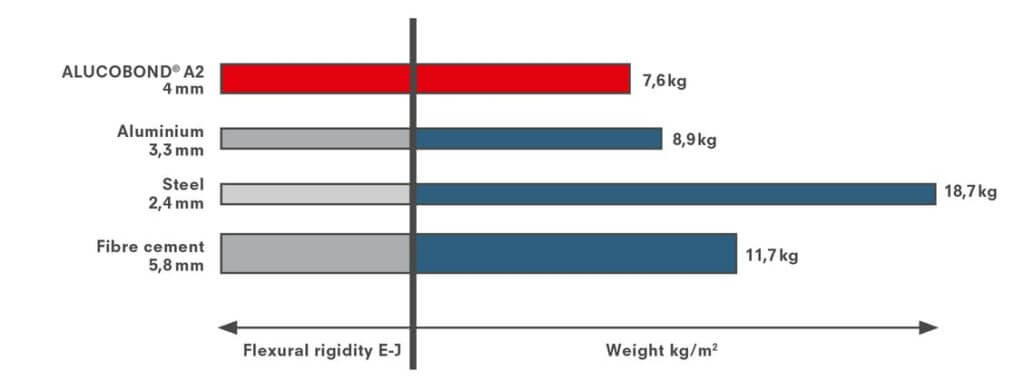

ALUCOBOND® A2 compared with solid aluminium

Required thickness and actual weights of panels with same rigidity

| ALUCOBOND® A2 | Aluminium | ||||

| Rigidity (E·J) | Section modulus | Thickness | Weight | Thickness | Weight |

| 1250 kN cm²/m | 1.25 cm³/m | 3 mm | 5.9 kg/m² | 2.7 mm | 7.3 kg/m² |

| 2400 kN cm²/m | 1.75 cm³/m | 4 mm | 7.6 kg/m² | 3.3 mm | 8.9 kg/m² |

TECHNICAL DATA

| Thickness | Standards | Unit | 3 mm | 4 mm | ||

| Thickness of Aluminium Layers | [mm] | 0.5 | ||||

| Weight | [kg/m²] | 5.9 | 7.6 | |||

| Width | [mm] | 1250 / 1500 | ||||

| Technical properties | ||||||

| Section modulus | W | DIN 53293 | [cm³/m] | 1.25 | 1.75 | |

| Rigidity | E·J | DIN 53293 | [kNcm²/m] | 1250 | 2400 | |

| Alloy / Temper of Aluminium Layers | EN 573-3 EN 515 | EN AW 5005A (AIMg1) H22 / H42 | ||||

| Modulus of Elasticity | EN 1999 1-1 | [N/mm²] | 70’000 | |||

| Tensile Strength of Aluminium | EN 485-2 | [N/mm²] | Rm ? 130 | |||

| 0.2 % Proof Stress | EN 485-2 | [N/mm²] | Rp0,2 ? 90 | |||

| Elongation | EN 485-2 | [%] | A50 ? 5 | |||

| Linear Thermal Expansion | EN 1999 1-1 | 2.4 mm/m at 100ºC temperature difference | ||||

| Core | ||||||

| Mineral-filled core with polymer adhesives | ||||||

| Surface | ||||||

| Lacquering | Coil Coating Fluorocarbon (e.g. PVDF) | |||||

| Gloss (initial value) | EN 13523-2 | [%] | 30-80 | |||

| Pencil Hardness | EN 13523-4 | HB-F | ||||

| Acoustical Properties | ||||||

| Sound Absorption Factor | ?s | ISO 354 | 0.05 | |||

| Sound Transmission Loss | Rw | ISO 717-1 | [dB] | 27 | 27 | |

| Loss Factor | d | EN ISO 6721, Frequency range 100-3200 Hz | 0.004 | 0.005 | ||

| Thermal Properties | ||||||

| Thermal Resistance | R | DIN 52612 | [m²K/W] | 0.002 | 0.002 | |

| Thermal conductivity | ? | DIN 52612 | [W/mK] | 1.99 | 1.77 | |

| Heat Transition Coefficient | U | DIN 52612 | [W/m²K] | 5.83 | 5.80 | |

| Temperature Resistance | [ºC] | -50 to +80 | ||||

Wind load and permissible panel sizes

In Germany, the dimensioning of ALUCOBOND® façade systems is regulated by the general building inspectorate approval (abZ) No. Z-10.3-774. In the Technical Extras section, you can find this and other documents, including load tables, dimensioning aids and various design examples

FIRE CLASSIFICATION

| Country | Test accord. to … | Classification |

| Australia | AS ISO 9705 AS 1530.3 Indices EN 13501-1 | Group 1 material SMOGR A 0.630 m2 / s2 0 (ignitibility) 0 (flame spread) 0 (heat evolved) 0-1 (smoke developed) A2-s1, d0 |

Brand